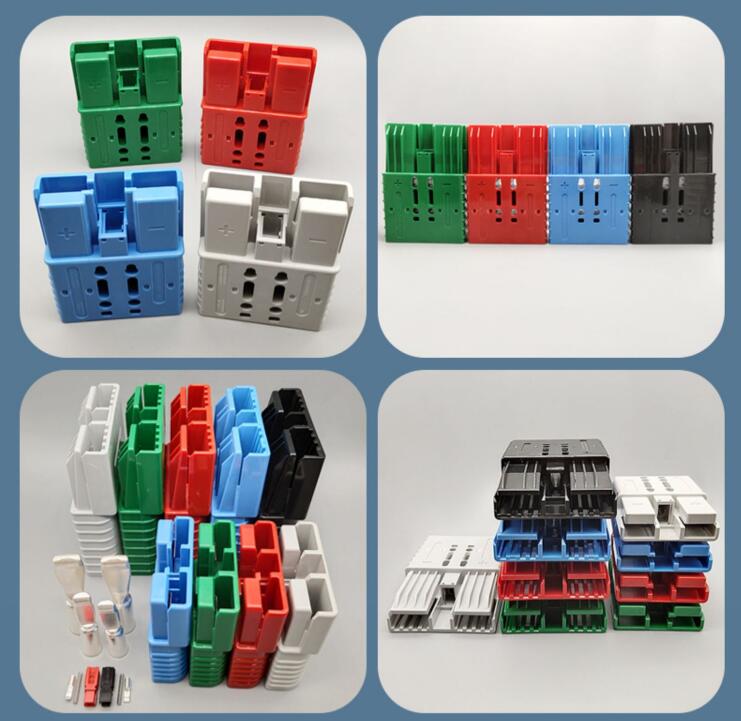

Plugs used for material handling equipments

Material handling equipment refers to a variety of tools, vehicles, storage systems, and devices used to move, store, control, and protect materials, goods, and products throughout the processes of manufacturing, distribution, consumption, and disposal. These equipment are essential in various industries, including manufacturing, warehousing, logistics, and construction, to improve efficiency, safety, and productivity.

Types of Material Handling Equipment

Transport Equipment:

Forklifts: Powered industrial trucks used to lift and move materials over short distances.

Pallet Jacks: Manual or powered devices used to lift and move pallets.

Conveyors: Systems that move materials from one location to another, including belt conveyors, roller conveyors, and chain conveyors.

Cranes and Hoists: Used for lifting and moving heavy materials, often in construction and manufacturing settings.

Automated Guided Vehicles (AGVs): Self-operating vehicles that follow predefined paths to transport materials.

Storage Equipment:

Shelving and Racking: Systems for storing materials in an organized manner, including pallet racks, cantilever racks, and drive-in racks.

Bins and Containers: Used for storing smaller items and components.

Mezzanines: Elevated platforms that provide additional storage or workspace.

Unit Load Formation Equipment:

Pallets: Platforms used to stack, store, and transport goods.

Skids: Similar to pallets but without bottom boards, used for heavy loads.

Containers and Totes: Used to consolidate and protect smaller items during transport and storage.

Positioning Equipment:

Lift Tables: Platforms that can be raised or lowered to position materials at the desired height.

Rotators and Turners: Devices used to rotate or turn materials for easier handling or processing.

Dock Levelers: Used to bridge the gap between a loading dock and a truck, facilitating the movement of materials.

Identification and Control Equipment:

Barcode Scanners: Used to track and manage inventory.

RFID Systems: Radio-frequency identification systems for tracking materials and products.

Software Systems: Inventory management and warehouse management systems (WMS) that help control and optimize material handling processes.

Applications of Material Handling Equipment

Manufacturing: Moving raw materials, work-in-progress, and finished goods within a factory.

Warehousing and Distribution: Storing and retrieving goods, as well as preparing orders for shipment.

Construction: Transporting and positioning heavy materials like steel beams, concrete, and machinery.

Retail: Managing inventory and moving goods within stores and distribution centers.

Healthcare: Handling medical supplies, equipment, and waste in hospitals and clinics.

Benefits of Material Handling Equipment

Increased Efficiency: Automating and streamlining material movement reduces labor costs and speeds up processes.

Improved Safety: Reduces the risk of injury by minimizing manual handling of heavy or hazardous materials.

Enhanced Productivity: Enables faster and more accurate handling of materials, leading to higher throughput.

Better Space Utilization: Optimizes storage space and improves organization within facilities.

Cost Savings: Reduces product damage and loss, and lowers operational costs through efficient material handling.

Material handling equipment plays a crucial role in modern industrial and commercial operations, ensuring that materials and products are moved and stored efficiently and safely.

Hotsale SMH plugs for material handling equipments:

SMH SY50A Battery Connectors Applications

SMH SY50A Battery Connectors Applications

Traction batteries plugs recommendation

Traction batteries plugs recommendation